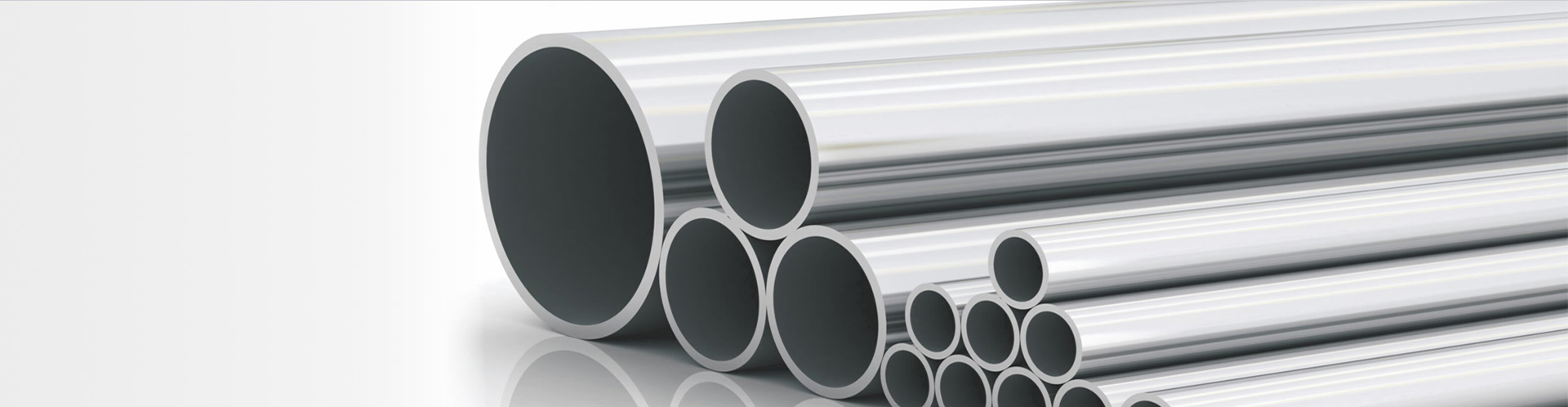

Wuxi Gotele Metal Corporation is a leading ceramic tile lined steel pipe manufacturer and supplier.

The cermic tile lined steel pipe utilizes the principle of ceramic-metal composite production technology, and special corundum ceramics made of AL2O3 as raw material and rare metal oxide as solvent through high temperature sintering at 1730°C are bonded, welded, inlaid, and riveted. Socket joint technology, a variety of wear-resistant ceramic pieces, brick materials composite wear surface in the pipe, thereby forming a surface with excellent wear resistance, and the matrix is still using ordinary metal composite pipe.

If you want to know more about our steel products or ceramic tile lined steel pipe price please feel free to contact us, we will reply you within 24 hours.

Technical Information of Ceramic Tile Lined Steel Pipe:

Physical Properties

Characteristics of Ceramic Tile Lined Steel Pipe:

The use of anti-fall porcelain tube, porcelain pipe inlay, so that the paste more flat, more solid.

The use of strong inorganic adhesive paste, wear-resistant steel bowl welding, porcelain tube and steel combined to form a double reinforcement to ensure that the porcelain tube does not fall off.

Ceramic tile lined pipe process welding sturcture

The surface of the porcelain tube is smooth, the running resistance is small, the scaling is unfavorable.

Flexible installation, high abrasion resistance, convenient processing and moderate cost.

Production Process of Ceramic Tile Lined Steel Pipe:

Steel body Grinding→ Ceramic patch→ Paste→ Welding→ Detection

* Use tools to clean the surface of the steel body.

* The raw material can be mixed evenly before use.

* The ceramic tube is pasted by professionals to ensure that the porcelain tube is free from the wrong side and the surface of the ceramic pipe is smooth.

* After testing qualified storage.

Why Ceramic Coating?

1. Ceramic coating is used by the OE’s extensively on 2007 & newer exhaust.

2. Ceramic coating is recommended for parts that are exposed to extreme heat.

3. Ceramic coating is used inside of chrome stacks to reduce the outside temperature of the pipe.

4. Ceramic coating will increase the longevity of the chrome stack.

5. Ceramic coating produces more usable power.

6. Ceramic coating protects parts from thermal fatigue.